EC-250 Router Features

- Designed with a lever throttle for safety (extra length for precise control in two-hand operation)

- To minimize unintentional start-up, but still have an instant shut off of the air supply, the lever on the throttle body has built-in resistance

- The router nose is easily adjustable for different cutting depth

- The shank of the router bit is supported by a high-quality bearing in front of the router nose

- The EC 2206 1/4 inch nose has a 1/2 - 20 I.D. Thread and the EC 2207 3/8 inch nose

has a 5/8-18 I.D. Thread to accept standard router guide.

- Front exhaust directs the exhausted air toward the work, removing the chips from the material being routed

- Specifications

- Speed – 25,000 RPM

- Length – 9 3/4 inches

- Diameter – 1 1/2 inches

- Weight – 2 pounds

- Collet Sizes – 1/4 and 3/8

- Minimum Hose Size – 3/8 inch

- Air Intake (FPT) – 1/4 inch

- Exhaust - Front

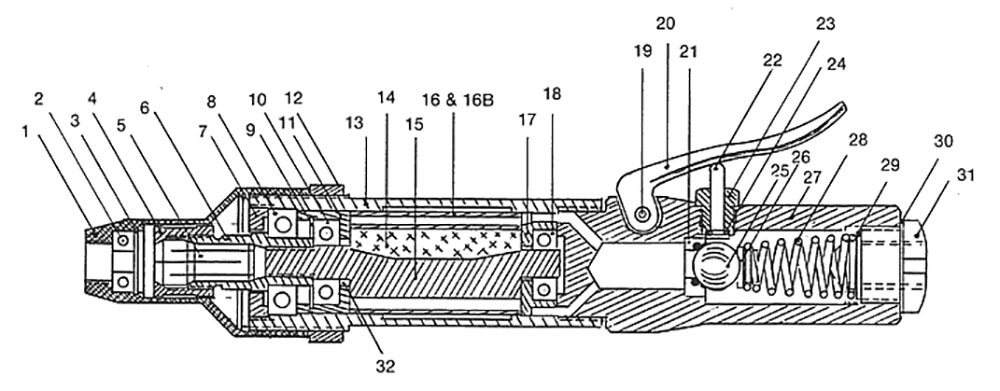

EC-250 Product Illustration

Click diagram to enlarge

EC-250 Router Parts List

Index, Part #, Description, Quantity

1 - See Chart Nose, 1

2 - See Chart Bearing, 1

3 - See Chart Retaining Ring, 1

4 - EC 8700 Collet Nut, 1

5 - See Chart Collet, 1

6 - EC 2522 Collet Spindle, 1

7 - EC 2523 Bearing Retainer, 1

8 - EC 9093 Bearing, 1

9 - EC 9376 Retaining Ring, 1

10 - EC 2100 Bearing (Front), 1

11 - EC 2524 Front Bearing Housing, 1

12 - EC 2525 Lock Ring, 1

13 - EC 2520 Motor Housing, 1

14 - EC 2070 Rotor Blade, 4

15 - EC 2060 Rotor-RH, 1

16 - EC 2050 Cylinder, 1

16 - EC 3162 Cylinder Pin (Not Shown), 1

17 - EC 2030 Bearing Plate (Rear)-RH, 1

18 - EC 2020 Bearing (Rear), 1

19 - EC 2310 Throttle Lever Pin, 1

20 - EC 2320 Throttle Lever, 1

21 - EC 8722 Valve Seat, 1

22 - EC 2360 Plunger, 1

23 - EC 2340 Bushing, 1

24 - EC 2350 O-Ring, 1

25 - EC 2380 Steel Ball, 1

26 - EC 8724 Spring Retainer, 1

27 - EC 2201 Throttle Body, 1

28 - EC 2390 Spring Tapered, 1

29 - EC 2400 Air Screen, 1

30 - EC 2410 Washer, 1

31 - EC 2420 Hose Adapter, 1

32 - EC 2080 Rotor Collar, 1

When changing Collet size: Order corresponding Nose, Bearing, and Retaining Ring. See below.

1/4 Collet

- EC 8703 Collet

- EC 2206 Nose

- EC 9015 Ball Bearing

- EC 9016 Retaining Ring

- Nose Thread 1/2-20

3/8 Collet

- EC 8705 Collet

- EC 2207 Nose

- EC 9019 Ball Bearing

- EC 9017 Retaining Ring

- Nose Thread 5/8-18

EC-250 Router Service & Maintenance Instructions

Operation:

The tool is designed to operate on 90 PSI air pressure using a 3/8 inch hose up to 8 feet in length. If additional hose is required, a 1/2 inch or larger hose should be connected to the 3/8 inch hose.

Lubrication:

An automatic in-line filter lubricator is highly recommended to increase tool life as well as keeping the tool in sustained operation. If in-line lubricator is not used, the tool should be lubricated several times daily by disconnecting the air hose and injecting a few drops of a high grade No. 10W machine oil in the air inlet.

Disassembly:

Remove Nose Assembly: Clamp the throttle body in a vise with the tool in a vertical position and remove Nose Assembly using a suitable spanner wrench.

Remove Motor Housing: Unscrew (right hand threads) the bearing retainer. The motor housing may now be unscrewed from the throttle body with the aid of a strap wrench, if necessary.

Change Rotor Blades: If the reason for disassembling the tool is to change the rotor blades, use a 1/4 or 5/8 inch brass or aluminum rod and remove the rear bearing and rear bearing plate from the rotor. By sliding cylinder off the rotor, the rotor blades can now be replaced.

Remove Collet Spindle: To remove the collet spindle or either of the bearings, insert a 3/16 inch allen wrench into the opening of the collet spindle and unscrew the collet spindle from the rotor. Now the bearings can be removed from the rotor.

Product Safety Warnings

For your safety, make sure you apply standard shop practices at all times when using this tool. Your failure to apply these practices may result in serious bodily injury.

Protect your eyes, ears, and other parts of your body by using safety equipment - respirator, safety goggles, ear mufflers and other necessary safety devices - at all times when operating this tool or when you are in the area where this tool is being operated.

For maximum stability and safety, only operate these tools with both hands on the tool. Follow the cutting tool manufacturer’s mounting and operating instructions and avoid any direct contact with the sharp cutting edges of the tool.

Modification or improper use of this tool, including, but not limited to, removing guards, mufflers, or other safety devices, voids all responsibilities of the manufacturer.

Excessive air pressure, over and above 90 PSI, will increase the RPM, the sound level, and can be a damaging factor to both the operator and the tool.

Stay alert! Watch what you are doing! Do not operates this tool when under the influence of medication, alcohol, or drugs!

Disconnect the air supply before changing the cutter and whenever making adjustments or repairs.

Do not remove warning tags until both sides have been read and understood by the person(s) responsible for safety in your plant.

If you need any other information, consult your supervisor or contact:

EC Eng. & Mfg., Inc.

P.O. Box 1090

Mountain Home, AR 72654-1090

Phone: (870) 425-3979

Fax: (870) 424-2228

Email: info@ecengmfg.com